|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We Need A Spoiler!! |

|

|

|

Well, then.....DO something about it!!! |

|

|

|

I'm making this car into a Plus, right?......the only 1990 Plus in existance. (And if Porsches have a cable shifter, because they are smooth and quiet, so can my car. I don't need no stinkin' loud, out of position, rattly, rod shifter!) So, I'd better get that spoiler on it PDQ. I got the spoiler several years ago, from Al Fitzgerald, back before he had to crush his cars. Somehow he had a new one in the box, and he shipped it to me. It had been laying around and laying around. I finally took it to be painted, and then it laid around for a long time more. Finally, the car is ready for it to go on. |

|

|

|

|

|

|

|

It's potentially rather traumatizing to have to drill big holes like these in my newly painted trunklid. So, thank goodness I had this previous Plus decklid with holes already drilled in it. All I had to do was make sure the spoiler I had fit these holes, which it did, then transfer the hole measurements to the new lid and drill away. I had had some not too happy experiences drilling in car bodies with a drill....wandering bit, eating paint, etc., so I was a little worried about that, but hey....ya gotta make an effort. So I jumped into this with both feet, and it came out pretty good. |

|

|

|

|

|

|

|

|

|

|

There are several ways to transfer the pattern for the holes from one lid to another....trace them out on paper; lay the spoiler down and mark where its fasteners touch the metal, etc. I decided to use a marker pen and a tape measure. About 300 years ago, in high school, I took geometry. That was the one math class I liked, and got a decent grade in. So I applied some of the triangle theory I learned there, and measured along the edge of the decklid, from the inner edge that butts against the back window, and a mark around the radius where it curves down toward the taillights. The pattern formed a right triangle, with the 90 degree angle about a foot in from the forward corners of the deck lid. I just formed two congruent ones, and away we went. (Pretty snazzy, huh?...I haven't used THAT word in 40 years, at least! Who says I'm OLD!!??) I was pretty lucky....the holes were within 1/8 of an inch of where they needed to be....good enough for me. |

|

|

|

|

|

|

|

|

|

|

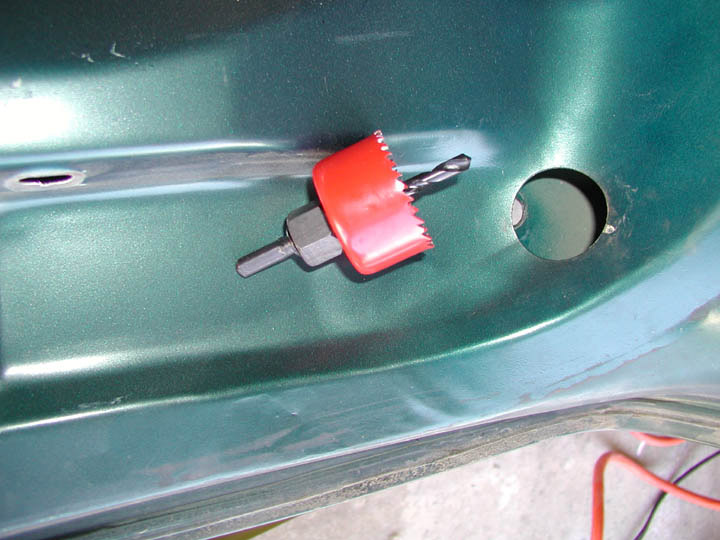

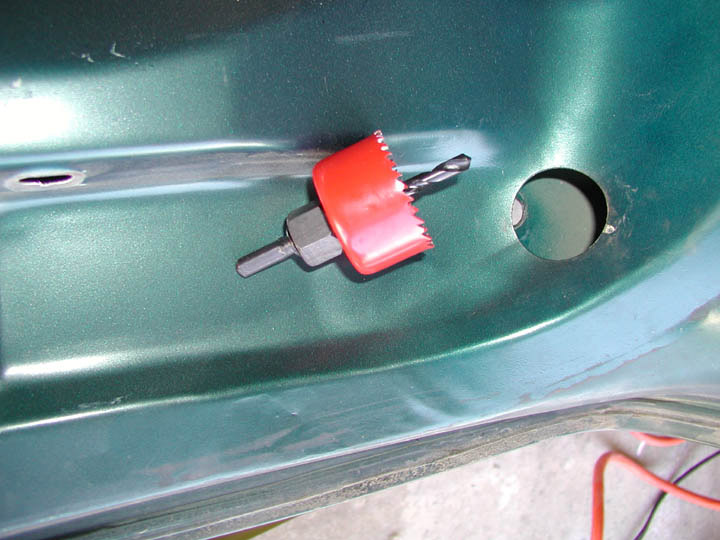

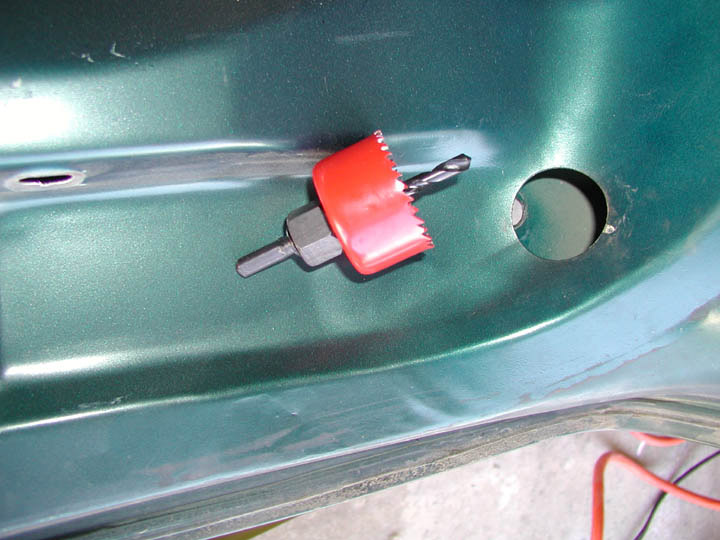

This little puppy right here was the secret to the whole job. It made drilling into the body about as easy as taking a breath of air. After I marked the spot for each hole, I just laid down the point of the drill on the spot, and pushed until it started to cut. Then I eased off and let the bit do the work. I already knew, by practicing, which layer I needed to go to, and it took less than 5 seconds for each layer to go through. After about three steps went into the metal, I was done. |

|

|

|

|

|

|

|

|

Looking at the donor decklid, you can see the extra holes I needed to drill in the framework in the corners of the lid. The 2nd and 4th holes were no problem, but the corners and center of the lid was where the framework was an inch or more down from the outer skin. So I had to use this hole saw to get through the frame, so that I could put the nuts on the fasteners for the spoiler. This wasn't quite as easy or as clean....the saw tended to wander around a bit. A drill press would have helped....but then I'd have needed two extra pairs of hands to hold the lid steady (besides going through the hassle of taking it off the car). Ah well...that's what filler and paint are for. |

|

|

|

|

|

|

|

|

|

|

Here I am going after it. I had to take the mechanism for latching the lid off, to get the release cables out of the way of the drill. I had to drill three holes, one in the center, and one on each end. |

|

|

|

|

|

|

|

|

|

You can see that the holes are a little rough. I think I can use some body plugs to fill them up. The outer hole is not as big as the inner one....I don't know why that area is the same color as the sky. The spoiler is on fine, and held in 5 places. |

|

|

|

|

|

|

|

|

Here are the holes as seen from the top, after all the drilling is done. This all took about 10 minutes. |

|

|

|

|

|

|

|

|

|

|

Again, the holes, looking across the lid. The spoiler went on just fine. I did not have a rubber gasket for it, so I used rubber sealer to coat all the lower edges of it that come in contact with the decklid. |

|

|

|

|

|

Finished!! |

|

|

|

|

|

|

|

I'm reminded by this shot of the rear to mention that I needed to convert the turn signals from the '90 style, combined with the brake lights, to the separate '91 style. I did that by removing the third wire from the combo brake/tail lights, and running it to an added turn signal socket, which was not present in the '90 taillight. A set of '91 taillights was obtained, and the t/s socket was added to the car's harness. Power for the brake lights comes from the high center mounted stop light on the package tray. A single wire needed to be cut on the harness that goes from the MFS, which combined the turn and stop functions. Thanks to Rich Bruso for the information about the MFS wire. |

|

|

|

Back Next Home |

|