|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wilwood Brake Swap |

|

|

|

|

|

|

|

The two of them face off....BD: ”OK...Who gets the Wilwoods!!??”

Lowrider: "What???? You have my wheels and my keyless computer....now you get the brakes, too????

Actually, Lowrider will get its MHT wheels back for the trip to Texas. BD is getting its black Plus wheels with these RD-730Bs (on the chrome slicers now on Lowrider). The slicers will not be used...they've deteriorated a bit while being on BD during its long periods of sitting. (They've since been donated to another BaySHO member.) I just want to get as much mileage as I can out of the Pilot Sports on the MHTs before they go permanently off the road. |

|

|

|

|

|

|

|

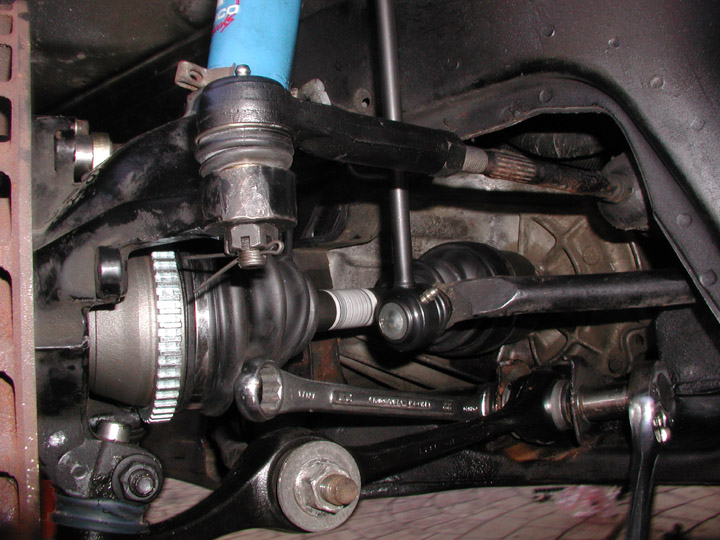

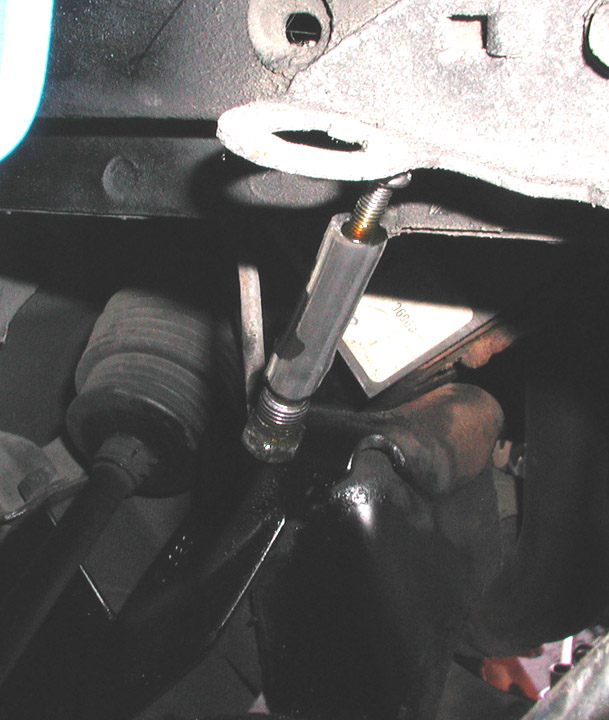

BD’s left side disassembled. The axle is in good shape, but I want all new stuff, so this one will go to Lowrider, which has a 150K+ mile axle on this side, and the boots are gone. |

|

|

|

|

|

|

|

Lowrider’s right side. I was going to swap the Tokikos, but they need a lot of cosmeteic work. They still handle pretty well, though. |

|

|

|

|

|

|

|

Lowrider’s right side coming apart. You can see the very tired axle that came off it, with the BD swapper next to it. |

|

|

|

|

|

|

|

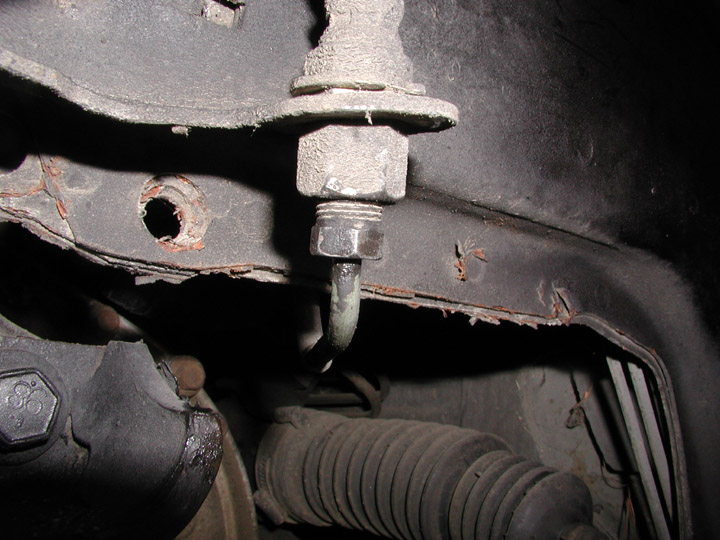

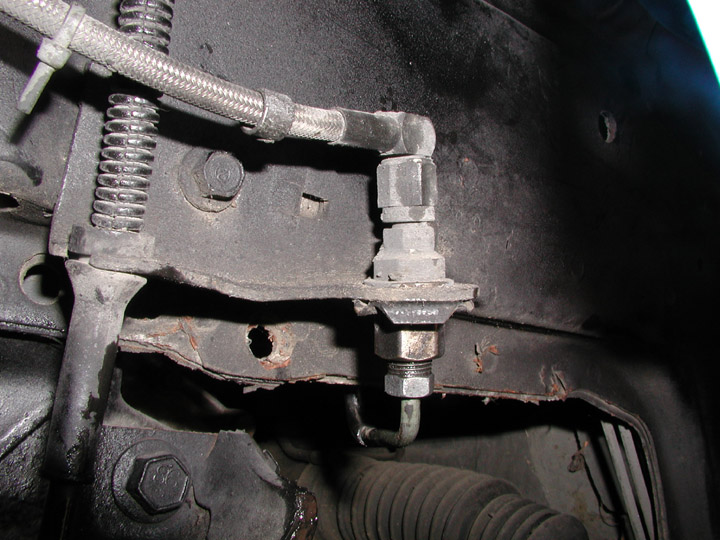

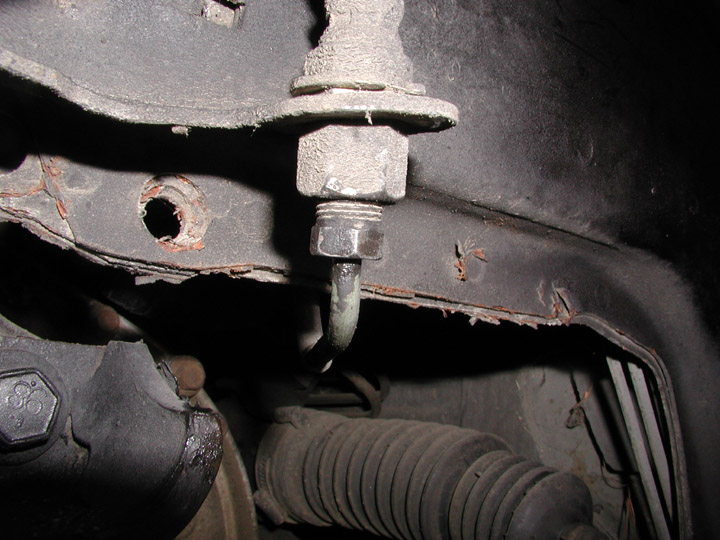

This is the part that was scaring me to death. It has been 16+ years since anyone (the factory) fooled with the brake lines on BD. We don’t have rust, but 16 years is a LONG time. Thank goodness I had the foresight to think of the rubber tubing with screws in the ends to use to seal the lines from the master cylinder. Both cars came apart just fine, and when I bled them, there were no air bubbles at all. |

|

|

|

|

|

|

|

|

|

Here’s a closeup of the brake line on Lowrider. It is definitely old, but with the right size wrench...an SAE 3/8 inch, it popped right off, as did the clip that holds the brake line to the chassis. This car has 293,000 miles on it....and I never have painted the suspension or subframe. Pretty good shape!! |

|

|

|

|

|

|

|

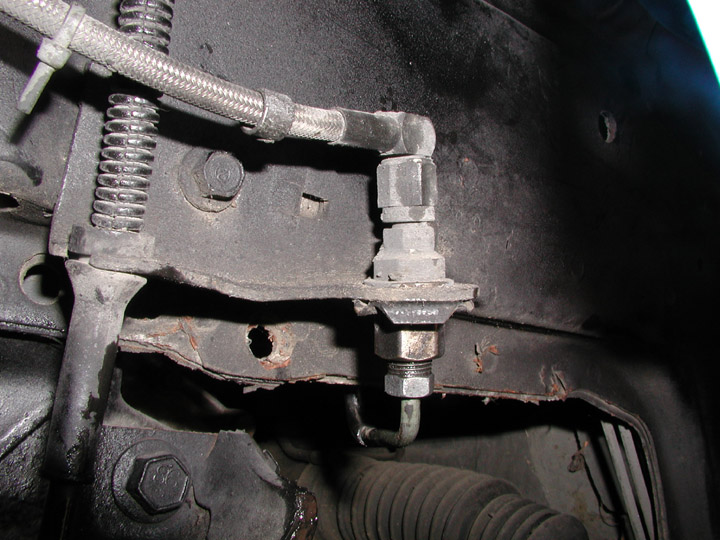

This is BD/s right side brake line....definitely less mileage (about 145,000) on this car. Maybe I can con the carSHO judges into thinking there aren’t ANY miles on it!! |

|

|

|

|

|

|

|

The LCAs came with bushings installed. That’s fine, except that my method of quickly removing the knuckles from the struts with just a shove depends on the LCAs sliding off the bushings on the tension strut after the rear bushing comes out.. If the bushings are one piece, that will not happen. They needed to be cut out, and the two piece bushings that Mark put in it while he had it need to be reused. I knew I had gotten that little saw a while back for a good reason. I originally got it to try to cut out the quarter windows. No way!! |

|

|

|

|

|

Home Stretch Ahead |

|

|

|

|

|

|

|

Here’s the right side of BD, all painted and pretty, waiting for the knuckle to go on. The car sure does feel good going down the road now. Later, with harder SFBs, it will be as good as it can get. |

|

|

|

|

|

|

|

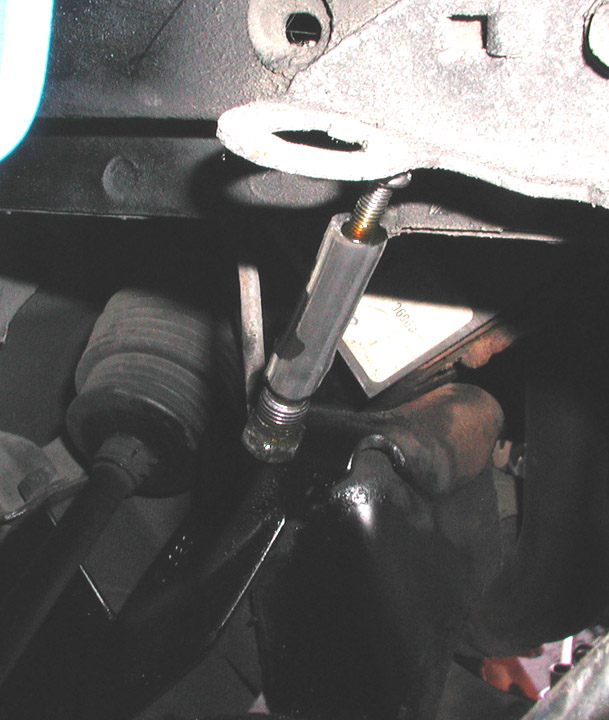

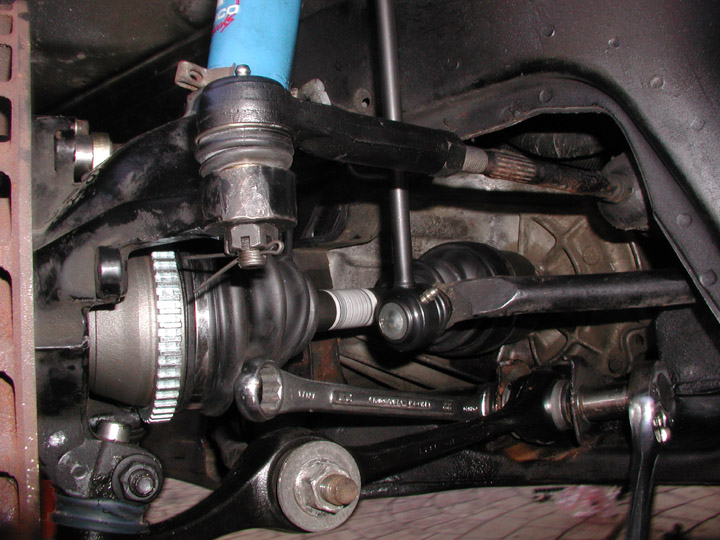

This picture illustrates the procedure for tightening the lower control arm inner bushing bolt. The bushing depends on the flexing of rubber compressed between the inner and outer metal sleeves. The inner sleeve has teeth that grip the flanges on the subframe when tightened, and the outer sleeve is pressed into the LCA. The rubber must be under zero tension when the car is sitting at rest. When jacked up, the spring pushes the entire knuckle/LCA assembly to its lower limit. If the bolt is tightened at this point, when the car is lowered, the rubber will be twisted near its limit in the upward position. When the strut/knuckle assembly retracts further upward, as in going over a bump, the rubber can shear, and when this happens there will be excess slop and misalignment of the knuckle/wheel. So to prevent this, the bolt is left untightened, but snug, so that the inner sleeve’s teeth can seat themselves in the proper position when the knuckle is jacked up so that the car’s weight is supported by the strut. When tightened, the inner bushing will be in the proper position. |

|

|

|

|

|

|

|

The wrenches are still here, but this is about as new looking a Gen 1 SHO front end can get. Hopefully it will last a long, long time. If Lowrider is any indication, it definitely will. |

|

|

|

Back

Home |

|