...and, it turned out...I needn't have changed the belt at that time...it still had its writing on the top side, and the teeth were perfect.

Four years later, in July of 2000, and about 65,000 miles farther, I was on the way home from the Indiana Convention, the Mille Miglia. The car had run perfectly since the timing belt installation, other than needing an EGR tube replacement, and was delivering 500 miles for every tankful of gas, since the a/c was inoperative due to a bad run of liquid lines that kept leaking after they were installed during my R-134 conversion earlier that spring. I was finishing up the next to last day of the trip home, preparing to check into a motel in Richfield, Utah. The car was under a covered entry way for the hotel, and sounds it made while running were reflected back to me by the building. I heard a soft banging sound as it idled, and wondered what that was. The sound went away as the speed of the engine went up. I shrugged it off as a noisy idler pulley, and didn't think anything more about it. In September of 2000, at our annual Fun Ford Sunday event, the sound was getting louder and louder, and the car was beginning to lose some power at speed, as well as drop off in fuel economy. As the fall progressed, the sound got louder and louder still, and I started to seriously worry about it. I jacked it up in the driveway, and took the various belts and accessories out of the picture to see what was making the sound, but even with both belts off, and the engine just running by itself, the sound was the same. The other worry that folks were mentioning was the wear that was showing up in rod bearings, but I knew the symptoms for that sound, as well as that of main bearings, and this situation did not match those scenarios.

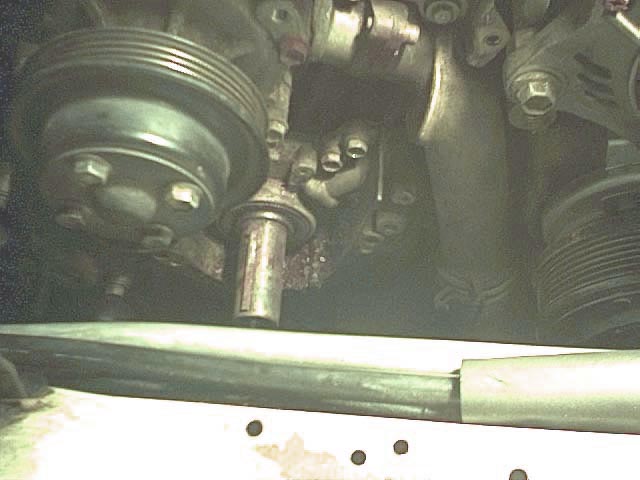

Finally, a friend came over to get some help with his suspension, and he said...try tightening the damper bolt....I had thought it would be tight already. I put a wrench on it, and tried to loosen it. It popped loose with no effort at all. AH HA!! Problem located....now we have to fix it.

It turns out that this crankshaft/timing sprocket/crank damper assembly is one of the weak links of the engine....there aren't many, but this is one. The sprocket and damper are kept aligned with just one woodruff key, and the entire sandwich is fastened down with one bolt which has to be torqued to about 125 pounds after assembly. The damper itself fits a little too tight onto the crank (ATX engines have a better fit...a damper puller has not been necessary the three times I've worked on the front of an ATX), so that the bolt may or may not actually transfer all its torque to the sprocket, which slips onto the crank and key easily, as long as there are no burrs or other damage to the key or sprocket keyway. Other engines (those I'm familiar with, anyway) are machined so that the damper can very easily be tapped into position with a small hammer, then the bolt applies its torque to all the components held in place, rather than the majority of the torque going to the damper alone. If this is the intended design, then there should be perhaps 3 key ways rather than one, since that one sprocket has the unenviable job of turning the camshaft(s) for the equivalent of three 4 cylinder engines...not an easy task. A better design would be to have the sprocket bolt to the crankshaft, rather than just be keyed to it and held in place by a very hard to tighten bolt. In the case of a car equipped with an automatic transmission, the bolt is almost impossible to tighten, since there is no way to lock the engine other than removing the starter and jamming the flywheel ring gear.

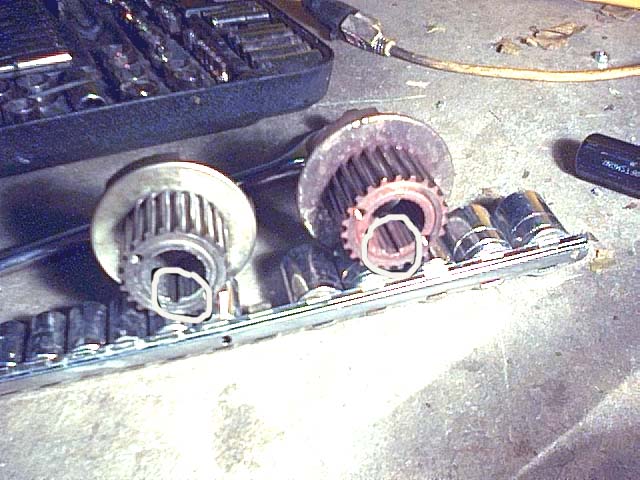

When I removed everything, I found that the key had been eaten away by about half its substance in the portion of it that held the sprocket in place, and the sprocket itself was correspondingly worn. The crankshaft also had been eaten away, by the gear sliding back and forth over it for all this time. If I had taken it to a dealer, they would have told me that I'd have needed a new crankshaft, and that would have finished off the car, since it was right at the 200,000 mile point, and not worth fixing.

I had a parts engine at the time, in the black car which has since been reengined, and so I got a good key and sprocket off of it. I asked the list for advice on the crankshaft, and a very nice gentleman by the name of Randy Crist sent me a container of LockTite 640, which is designed for situations like this, where space needs to be filled in between a gear or pulley and a solid shaft. In addition, I used a .0015 feeler gauge that was cut into thirds, and slid under the new sprocket, since that was the amount of wear on the crankshaft. All of these components have held up nicely; now the car has 282,000 miles, and things are running just fine. This car was one of the first to have this condition, which I call "Crankshaft Cancer", and I have been happy to assist other folks on the list in their diagnosis and repair of the same conditions. Since it would be very difficult to remove the sprocket again, I replaced the still original oil seal, which was not leaking, but probably was getting close. I finished the 60K service by replacing the water pump and CPS again....now there would be no need to go into the front again for the rest of the life of the car. When it started after just a couple of compression strokes and idled quietly, I was very satisfied, and quite grateful to the list for its help.

Summarizing, this condition is caused by the improper tightening of the crank damper bolt, which is easy to do, as mentioned above. One needs to make sure the engine is locked up tight, and the proper torque applied to the bolt, otherwise the problem will occur again.

Thanks again, Randy.