The Boss was my second new car. The first was a 1965 Mustang GT hardtop that I got in the late summer of 1965. It was a terrific car...Mustang sportiness, plus it was the first car in my family to get any kind of fuel economy. We had had Buicks up til then, and I had been introduced to heavy luxury cars ever since I learned to drive at the ripe old age of 8 years. The '65 was my 'High School' car, but I didn't get it until completing my first year of college, at good old Fresno State College, now known as Cal State University at Fresno. So, after almost 4 years of dependable use, the '65 Mustang was traded for the Boss, which was one of the first 6 Bosses to come to California. The dealer wanted to give me $800 for it, but my Mustang Club Advisor/Salesman friend got them to go up to $1200. I would have been fine just keeping the '65, but my father wasn't into collecting cars, like I am. It was sold in just a couple of weeks, and I saw it in town. The new buyer was very happy with it, and it performed well for him.

(There might be a picture or two of the '65 around...if I find one I'll stick it in here somewhere! It was originally red with red interior and a white stripe; later painted bright yellow with a red stripe outside, keeping the red interior. You either loved it or hated it....!!)

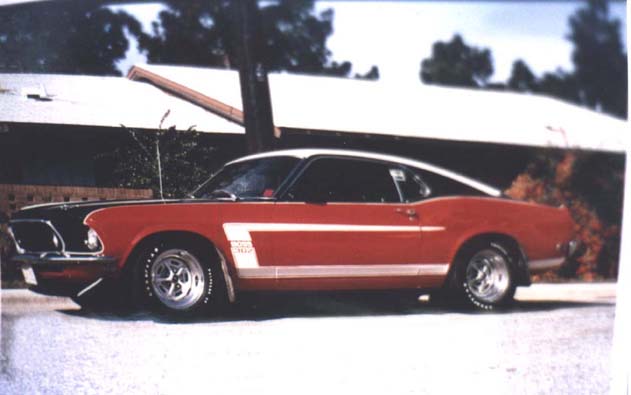

I put a deposit of $50 on the Boss in March of 1969, and picked it up in late April. It was the first Boss to come to Fresno, and stayed on display in the showroom for a couple of weeks, until I was able to go in and pick it up. Unfortunately, the dealer took all the paperwork off of it, including the window sticker, and I never saw any of that material...too bad. As the first batch of a first run car, it had some problems, including not having the specified Gabriel shock absorbers, very weak pistons, and some squeaks and rattles that I had to disassemble it to find. As with the Lowrider, it took me several years of experimentation and modifications to make it into what it should have been from the beginning. It took a year to get the ignition timing correct...it had one of those dual diaphragm vacuum advance/retard junkers. It was also the only 1969 Ford engine required to have a smog pump, as opposed to all the rest of the F/LM line for that year, as there weren't enough Boss 302 engines made for Ford to bother certifying, even though it was just as clean as the rest of them.

It spent the first 9 months of its life in California, then went to North Carolina with me as I began my tour of duty with the USAF, flying C-130s at Pope AFB. That is NASCAR and NHRA country, so it was at home in the South.

When I first got to North Carolina, I figured that since I had a ‘new' car, I could get a junker to play with, since I wouldn't need to be working on the Boss. (Ha!!) So, I went down to one of the local lots where there were some old cars, and found the perfect stall mate for the Boss, a ‘63 Falcon Futura convertible, with a 144 CID 6 engine, and a 3-on-the-tree! What a great car. Paid 200 bucks for it...ran great, except that it didn't have a 2nd gear, and the top was more duct tape than factory equipment. It had black interior, and was dark maroon outside, in between the rust and dents. It ran good, though, and after I figured out how to smoothly skip 2nd gear, I was fine. My good friend at Pope called it the ‘purple grape'! Over time, I replaced the engine, with a 200CID Mustang 6 cyl., rebuilt the transmission twice, replaced the top, the two front bucket seats, and replaced the brakes, shocks, and tires. I took the Boss to Nashville, Tennessee, for C- 130 transition, and raided a wrecking yard that had all these parts except the engine, and brought them home, INSIDE the Boss, with the convertible top, rails and hydraulics, wrapped around me as I drove down I-40 at 75 mph!! The seats were in the back seat, and the tranny and other small parts were in the trunk. Someone else took my luggage by air, as I was totally maxed out with car parts!!! It turned out I used the Falcon for my daily travels for the first year I was there, as the Boss had lots of troubles. The bad news started with it cracking a piston skirt during the trip to Pope, and, as we did a lot of auto-crossing in California, and the selling dealer gave me a set of installed exhaust cutouts for that, the dealer in Fayetteville thought I was drag racing, and voided my warranty on the engine. I dutifully paid the $81 (!) it cost me to have a new piston installed, thinking the warranty would be reinstated. Later that year, I drove it home to California, via the Pacific Northwest, and cracked the other 7 piston skirts. This little problem most likely occurred during the day that I covered 860 miles in 10 hours, driving across Montana for the first time. I was lucky enough to drive over about 100 miles of Interstate 90, between Billings and Butte, during its first day of service. I cruised on the freeway for hours at 4500 rpm, which is about 95 mph. I remember having some squeaky ball joint trouble during that time as well, and after arriving at Deer Lodge, and deciding to stop there for the night, I installed a right upper ball joint while pulled over to the side of the road, which I had purchased at an auto parts store in Billings earlier that day. The engine ran perfectly all the way to Seattle, where I spent a few days visiting my relatives, then roared down I-5 to home, in the central valley of California. The next morning, after arriving home late, I got up early to drive the car in to Fresno to show off its new Bud Moore Trans Am paint job to my previous Mustang Club friends. I started the engine, and I thought it was going to go all directions at once...it made so much noise. I drove it gingerly into the dealership, and the service folks said, 'yep...it's the pistons. We'll look up your warranty and order the parts we need.' They came back a few minutes later and said...'oops, you don't have one....the dealer in North Carolina voided it!' Thanks a lot, folks!!!! So, I did an in-frame overhaul in a friend's driveway, a few blocks from the dealership, pushing it down there to have the cylinders honed. The only problem with that was, even though I put high quality Mickey Thompson 12:1 pistons in it, with all the best parts everywhere else, I didn't realize there were different honing stones for different types of rings. I didn't tell the shop that it would be getting Chrome Moly rings, and they honed it for cast iron. Exactly how much oil do you think it burned by the time I got it back to North Carolina, 3000 miles away? It burned a quart every 80 miles, and smoked out those two rocker exhausts like a really old diesel truck!! I had to stop for oil more often than gas!!

I put some all chrome rings in it, and took it out to a drop-zone access road in the boonies of Fort Bragg to break it in...the shop said to run it from idle to redline in second gear about 6 times, and I did just that...it was done in just a few minutes, with no more oil burning problems...at least for a while. It had at that time, and when the picture above was taken, JR Headers, which had 4 inch collectors. These went into a 15 inch Thrush turbo-glass pack, and then out the tailpipes, which were also 4 inches in diameter, and emptied in front of the rear wheels on both sides. It sounded AWESOME, just like a NASCAR or Trans Am stocker. The problem was that the headers extended down quite a bit from the heads, and with the lowered suspension (via the 1 inch lowered A-arm Shelby trick), they hit the ground on some of the bumpy sandy streets that were on the base, and kept breaking motor mounts. I finally removed the JRs and installed Hedman Hedders, which fit the body a lot better, but interfered with the oil filter, and every second time I'd start the engine after a filter change, it would blow the oil filter seal out. I finally had to dimple the #5 pipe so that the filter would fit properly.

Lots more coming.....including the conversion to Propane fuel, and being sandblasted twice, while being repainted at least 10 times over its life...and being attacked by ...rabbits!!

In 1971, when it was two years old, I was assigned to a C-130 wing stationed in Taiwan, to begin my first of two tours in the Viet Nam War. On the way west from North Carolina, I would spend two weeks in Spokane, Washington, going to the Air Force's Basic Survival School. What an adventure that was. It was in March of the year, and we went on our ‘trek' up in the mountains of Pend Oreille County (pronounced Pond O-rey). What a beautiful area!! Anyway, on the way home, down I-5, in northern California, just above Weed, I had a flat...actually I had a massive tire failure. Now, remember, I am on a PCS move halfway around the world, so everything I owned that wasn't shipped was with me in the car. Any of you who have ever owned a smallish car with big tires and wheels knows what happens if you have a flat....you toss the flat tire in the back seat and carry it to be fixed...it won't fit in the trunk....this car had F60-15 Polyglas tires, and the flat wouldn't fit any place in the car but one....on my lap. So, in the dusk, having driven all day from Seattle down to northern Ca, I got to drive about 70 miles with this tire in my lap, and the gas charged inflatable spare on the ground. I had to bend down and look through the center hole of the wheel to see where I was going....the tire was totally shredded and there was no tread, just sidewalls and flailing polyester cords going everywhere. I know exactly where I changed it, and to this day whenever I go by that bridge, I tell my passengers...."that's where I had a huge flat 29 years ago!!" It looks exactly the same now as it did then...high desert, with no inhabitants, and under the shadow of Mt. Shasta.

The best engine it ever had, of the numerous overhauls it has endured, was the one I built in North Carolina, with the chrome rings and Mickey Thompson pistons. Unfortunately, there was one thing I didn't reinforce when I built that engine....Ford small-block builders will know what I mean...the Teflon-toothed timing chain set. I didn't realize how weak that setup was, and neither did Ford, I guess. I never could imagine why they would install a cam drive in that engine that was supposed to be quiet, since it had solid lifters anyway, and required periodic valve adjustments. So the chicken finally came home to roost when I came back from Taiwan, and started driving the car again, after it had basically sat for almost 3 years. What happened was, the Teflon/plastic teeth started to break off the gear, and allowed a LOT of slack to occur, allowing the cam to be retarded almost 10 degrees. I had been away from the car for all this time, and had forgotten some of my tuning experience and tricks. (All I had to do was rock the damper back and forth, and I would have found the problem...slapped a dual roller timing chain and gear set in, and it would have been fixed....naah, not me....!!) So, the car was more and more sluggish, and didn't have the power it used to. I kept playing with the timing, which is all there was to play with, as far as I knew, and finally it gave up, overheating on a 90 mph run, blowing antifreeze all over the fenders and hood, which permanently discolored the paint by the time I got it where I could hose it off, and now there was a knocking coming from the engine, which varied with engine speed and load. I got it home and took the spark plugs out, and found #7 with a broken and missing electrode. The car ran on all cylinders, but made very little power. A few days later I made arrangements to stay at a friend's house while rebuilding the car closer to machine shops and parts...I was on 30 days of leave, at my home in the country, (boonies) from the Air Force, getting ready to go fly KC-135 Tankers at Spokane's Fairchild AFB, where I had been to survival school 3 years before.

As soon as I started to disassemble the engine, I found the chipped gear teeth in the oil pan, and I immediately knew the cause of the problem. What needed to be determined now was the overall damage to the engine. It turned out I had collapsed a piston due to failure of the oil under extremely high temperatures caused by the high compression and the very late valve timing. The #7 piston was .025 inch collapsed compared to the other ones. Also, the cylinder wall was scored about .020 deep in 3 or 4 areas, and would need to be bored to remove the scoring. At the time, the Mickey Thompson pistons were out of production, and no one knew where I could take one to be copied...there were also no Boss pistons available in a .020 oversize with my compression requirement. A company called Venolia made pistons for the engine, but there were currently none to order, so I had to go with TRW stockers, lowering the compression down to 10.5 to 1. This really ate into the performance and economy of the propane conversion...remember, it requires the higher compression to utilize the lower BTU capabilities of propane. I got a factory replacement block and got it together, and noticed two things almost immediately...it had no power, and it had no oil pressure. I have an ammeter and mechanical oil pressure gauge pod down where the ash tray used to be...no smoking in any of my cars...!! I'd had the crankshaft out of it twice, and had it polished both times...so now, I am running undersized journals, and this particular shop gave me standard bearings. At idle, it had about 12 lb of oil pressure, and at 2000 rpm it had about 30 pounds. (Sound familiar?) Normal pressure for this engine is between 55 and 60 lbs at 2000 rpm. The solution, for the time being, was to install .002 undersized connecting rod bearings, which brought the oil pressure up to a reasonable value.

After coming back from Taiwan, I was assigned to Castle AFB in Merced, Ca, to transition to the KC-135 tanker. During that winter, the rains flooded the roads in some spots near my house. I remembered one day that long ago, with the ‘65 GT, I used to have fun running the right wheels through puddles going fast and watching the water fan out in a huge spray. There was a place where a puddle covered the whole road, and ...remember, it had been a long time....I thought...wow, what fun!! At 60 mph, it got waterborne, veered to the right a little bit, due to my weight, and slid right into a big pile of sand, used for road repair out in the boonies. I twisted the front end, wiped out the hood, because it was pinned to the radiator support, popped the radiator with the fan, and caved in the lower panel below the bumper. As the car came to rest, it wiped out the rear lower panel below the bumper as well...pretty thin sheet metal all around. It ran and drove OK, but because it had no coolant it was towed to the body shop. I worked off the deductible taking it apart, and the shop did an excellent job of fixing it. We ran the car for hours to heat the shop, and after getting used to the odorizer, we were relatively warm. For some reason I decided to not paint it immediately after it was fixed...we just left it in primer. I think it might have been because I needed to report to Fairchild, and so it was in primer from the belt line down, and black and white on top. Later on, I painted it all red, the proper Ford dark red, with black stripes, and it looked darn good. It stayed that way for two years, at which point it went back to the proper Bud Moore colors.

This all occurred in 1977 and '78. The paint held up for several years, but the clearcoat finally got to the point where it would not hold a shine. I'd have to wax it every few days with Classic car wax, and I found that if I didn't use my fingers only, no rags of any kind, it would streak and scratch worse than it was before I started. I put up with it until the middle ‘80's, when I discovered that one of the squadron commanders of my reserve wing was a car nut, and was going to the local community college to learn bodywork and painting. After he got his shop going, I took the car to him to be painted again. It was suggested that it be sandblasted again, because the new paint they would be using might not be compatible with what was there from before. This time, it was totally acrylic enamel, with hand masked stripes, masked by me and painted by the shop, then a clearcoat acrylic layer over everything, preventing chipping of the stripes and collecting of wax between the various colors. This is the paint that is on it now, and it has held up well, requiring little maintenance up until the time the car was finally retired while I lived in Bakersfield and purchased the Turbo Coupe.

In the years between 1979 and 1981 (pre-FAA), I was living in the old "Model Garage", in Suisun City, just next to Fairfield, and was kind of 'in between jobs' flying C-5 trips every few weeks, and the rest of the time I worked locally for a guy who ran the marina just next to our house. He and a business partner had come up with the idea of designing boats that looked a lot like '80s Dodge Maxivans, and had a fleet of 20 or so that he rented out for days or weekends. While all this was going on, for whatever reason, the Boss needed another engine overhaul....too long ago to remember exactly why. But I sure remember what happened after that rebuild occurred....after about 500 miles of gentle driving to break it in, it would slowly start blowing blue smoke, and got worse and worse over time. I thought I had done something wrong, and yanked that engine out again, and re-ringed it again. The same thing happened, after about the same mileage. So out it came again, this time the short block being assembled by the shop where I was getting the parts. Same story again...500 miles and it is a worn out Peterbilt! I'm not sure how I found out, but it had to be running on gasoline to break the rings in...propane has no additives and is the wrong chemical formula to allow the rings to seat properly. So, ONE MORE TIME, it came out, and this time I put a portable 12 gallon auxiliary tank that I had kept from the '65, giving it a lot more range, onto the passenger side front floor, with the fuel line running out the slightly open window, and up to the engine with the hood hinge adjusted to its highest position so the hood could shut and let the line go in. The tank stayed in the car for about 3 months, while I commuted to my new job with the FAA, about 55 miles of freeway one way. This time it broke in properly--FINALLY-- and I had no more trouble with it....except....a LONG time ago, I had had the engine balanced, and the shop ground the flywheel a little bit off, just enough that above 4K RPM it started to shake pretty bad. I drilled a hole in the bottom of the bell housing so I could get to the clutch bolts to flywheel, and did my balance trick to find the light spot. I used an inch longer bolt for that spot, and put about 6 washers on it, and that took care of it enough that I could drive the car and not get my teeth shaken out. After that was taken care of, I had no more problems with it.

During the time the car has been in storage, down on the ranch where I grew up, it has been in a farm implement storage shed, with a cement floor, but other than that, not protected particularly from the cold....it has been covered and dry, but is dusty and cold. One relatively recent winter, it was VERY cold, and a family of rabbits made their way into the shed. I had three cars stored there, the Boss, and the former, now sold 'Token GM's', the '68 GTO and the '63 Riviera. The Boss had the misfortune to have a relatively small engine in its bay, so the rabbits could make their way up to the top, and devour the silicone spark plug wires and some of the wiper harness. While on the ground, they ate the brake lines, up until they got to the fluid, and gnawed on the mudflaps it has always had, which protect the rocker panels from rocks and road debris. While gnawing on them, they chipped some of the paint on the front fenders, and so, to pass close inspection, it would need another repainting. The insurance company was amazed at the claim, but they paid it...I keep $0 deductible comprehensive on all the cars....even the stored ones. They replaced the wires, brake hoses, paid a dealer to rewire the wipers, and bought me new mudflaps, and paid about 600 bucks for repainting the front fenders, which did not get done. I was as amazed at this whole thing as the insurance company was. When it is on the road again, it will get touched up where the fenders are chipped. There are just a couple of places where primer shows, and these can be fixed with very careful application of spot painting.

It was last registered in 1995, and was very happy to be out of its prison. It has been back in the shed since then, and is ready, I'm sure, to be brought out into sunlight again. I always crank it with no spark first, to prime the bearings. It always starts instantly, due to the propane staying volatile, and ought to be easy to start the next time I visit.

Update on September 15, 2009....it has moved well up the list of things to do, and hopefully will start as a restoration project sometime later this fall. I've been shopping for parts, and the majority of what it needs is widely available. It will never be concours, but it will be its own unique entity. There is a good sized active Mustang club in the local area, and I will enjoy driving it to local events after it is back on the road. To quote Waylon, maybe it's time to get back to the basics of life.

All is not lost at this house, however. An annuity from my parents is beginning to become accessible, and there might be funds in it for me to either get another 'G' code (real Boss VIN code) car to restore, or find a suitable sportsroof (no Mach Ones) and make a clone. There is a Mustang store in Sacramento, with a big shop behind it which restores all sorts of Mustangs, and I have talked to the bosses. They say either way is good if I am going to keep the car, rather than try to make money flipping it, and the clone or Boss can be restified with current technology to build a really nice car. I want it to be red, white, and black, with white stripes, like the Bud Moore cars were, but the paint will all be metallic pearl, with high quality clearcoat on top. There will be a big white round spot on each door, with the number '15' in it, and in cursive on the driver's side roof will be the text "Driver, Parnelli Jones". That might not happen for 2 or 3 years, because there are other 'bucket list' items to be done, but it will happen.

Thanks for reading.